| This is the beginning of the tire master. Again I utilized PVC from the hardware store; this time a plumbing fitting that was just about the right size. It was a little thin on material where I wanted to make the sidewall, so I built it up with some CA so I could have more curvature to the sidewall. |

|

|

|

| I cut the sidewall on the lathe freehand but used traditional tools to cut the bead; the tread was cut on the mill. The tread is patterned after an Advan tire. |

|

|

|

| I added the sidewall detail and lettering. |

|

|

|

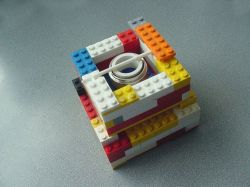

| I use Legos to make my mold frames. (The plug in the center of the tire master is made of Renshape.) |

|

|

|

| Not only are the Legos easy to work with and reusable, they also can be stacked to fit more molds in the vacuum/pressure vessel. This is the rim master on top of the tire master to cast the first half of the molds. |

|

|

|

| Here is the mold and a casting from it for the outer rim for the wheels. |

|

|

|

| Here is the first cast tire on the first cast rim outer. I cast both parts from molds I made off masters I created. The tire is hollow and easily stretches over the one piece rim. It is so soft and pliable that it should “squat” under the weight of the car. |

|

|

|

| Back: |

|

|

|

| I’ve been casting centers for the wheels too. Still not sure which design I’ll use, the five spoke or the web, or maybe something different all together… |

|

|

|

| Here’s the set of five tires and outer rims I have made for it. I’m ready to get back to part and pattern making. Prototype work is more rewarding than “production” work. |

|

|

|